PR8 / SR8

ROTARY PACKAGING MACHINES FOR PREFORMED BAGS

PR8 is an automatic rotary alternating packaging machine used for medium and large sized preformed bags suitable for food, pharmaceutical, cosmetic sectors easy to use and maintain.

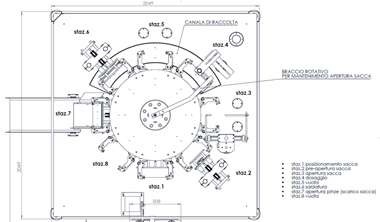

It is made up of a carousel with 8 stations: bag pick up and insertion of the same in the carousel, pre-opening of the bag, opening of the bag with suctions caps and pneumatic grippers, product dosing, sealing, second sealing (when necessary) – unloading into the conveyor belt slide exit.

For each station there are 2 mechanical grippers with traction springs that grants the grip of the bag during the all process. With PR8 it is possible to pack different formats and types of bags. The format change is quick and it takes about 10 minutes. All the control functions are displayed on a touch screen panel from which it is possible to set the recipe and the change the format.

All the components in contact with products are made of stainless steel AISI 316

It is made up of a carousel with 8 stations: bag pick up and insertion of the same in the carousel, pre-opening of the bag, opening of the bag with suctions caps and pneumatic grippers, product dosing, sealing, second sealing (when necessary) – unloading into the conveyor belt slide exit.

For each station there are 2 mechanical grippers with traction springs that grants the grip of the bag during the all process. With PR8 it is possible to pack different formats and types of bags. The format change is quick and it takes about 10 minutes. All the control functions are displayed on a touch screen panel from which it is possible to set the recipe and the change the format.

All the components in contact with products are made of stainless steel AISI 316

TECHNICAL INFO:

PRODUCTIVITY * : aprox 25 bpm

FILLING VOLUME : fino a 3000 ml

BAG DIMENSIONS : width 60 ÷ 320 mm X height 100 ÷ 400 mm

POWER CONSUMPION: 5 KW – 400V/3F/N/T – 50 Hz

AIR CONSUMPTION : 200 Nlt./min. at 6 atm

PLAN DIMENSIONS ** [mm] : 2050 x 2050 + bags warehouse

WEIGHT : aprox 3000 Kg with accessories

• * SUBJECT TO VARIATION BASED ON THE TYPE AND QUANTITY OF PRODUCT TO BE PACKAGED • ** SUBJECT TO VARIATION BASED TO DIMENSION OF THE BAGS TO BE PACKAGED

FILLING VOLUME : fino a 3000 ml

BAG DIMENSIONS : width 60 ÷ 320 mm X height 100 ÷ 400 mm

POWER CONSUMPION: 5 KW – 400V/3F/N/T – 50 Hz

AIR CONSUMPTION : 200 Nlt./min. at 6 atm

PLAN DIMENSIONS ** [mm] : 2050 x 2050 + bags warehouse

WEIGHT : aprox 3000 Kg with accessories

• * SUBJECT TO VARIATION BASED ON THE TYPE AND QUANTITY OF PRODUCT TO BE PACKAGED • ** SUBJECT TO VARIATION BASED TO DIMENSION OF THE BAGS TO BE PACKAGED

COMBINABLE DOSING SYSTEMS:

BRUSHLESS VOLUMETRIC DOSING MACHINE

SCROLL DOSER

MULTI-HEAD WEIGHER

MULTI-HEAD WEIGHER

LOBE PUMP WITH ELECTRONIC CONTROL

MAIN ACCESSORIES:

BAGS WAREHOUSE (HORIZONTAL OR VERTICAL)

ACCESSORY INSERTION (ex. superior or lateral cap)

EMPTY GROUP

GAS INJECTION

UNITY FOR HANGING HOLE OR EUROPEAN HOLE

BRUSHLESS VOLUMETRIC DOSING MACHINE

SCROLL DOSER

MULTI-HEAD WEIGHER

MULTI-HEAD WEIGHER

LOBE PUMP WITH ELECTRONIC CONTROL

MAIN ACCESSORIES:

BAGS WAREHOUSE (HORIZONTAL OR VERTICAL)

ACCESSORY INSERTION (ex. superior or lateral cap)

EMPTY GROUP

GAS INJECTION

UNITY FOR HANGING HOLE OR EUROPEAN HOLE

Request a quote for

ROTARY PACKAGING MACHINES FOR PREFORMED BAGS

Fill this form