ROBODEV

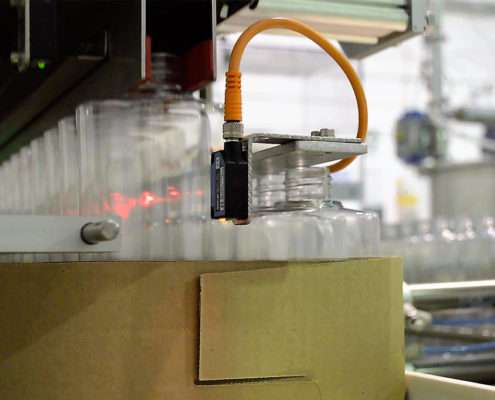

Automatic plastic and glass bottles tray denester

Robodev is an automatic bottles trays denester for plastic and glass bottles of different sizes and dimensions.

With 2 translative axis and the thrust plane our bottles tray denester is able to feed the conveyors of the production lines with high speed and constant perfection

The machine was designed with the aim of obtaining high performance in a small place with considerable autonomy, thanks to the double loading tray . The configuration of the machine can also be studied ad -hoc doc for the customer’s needs.

With Robodev the sets up time and the expensive format change that occur with traditional unscrambler are eliminated, granting high productivity in a small working place.

The interchangeable gripping unit allows the gripping of any bottle format (elliptical, oval , cylindrical , jar ) of different materials (PET , PE , glass )

With ROBODEV a few movements will be enough to change the type of bottles in the production lines. Through the machine control panel the operator is able to set a format change in a few seconds, save new recipes and modifying the existing ones

With 2 translative axis and the thrust plane our bottles tray denester is able to feed the conveyors of the production lines with high speed and constant perfection

The machine was designed with the aim of obtaining high performance in a small place with considerable autonomy, thanks to the double loading tray . The configuration of the machine can also be studied ad -hoc doc for the customer’s needs.

With Robodev the sets up time and the expensive format change that occur with traditional unscrambler are eliminated, granting high productivity in a small working place.

The interchangeable gripping unit allows the gripping of any bottle format (elliptical, oval , cylindrical , jar ) of different materials (PET , PE , glass )

With ROBODEV a few movements will be enough to change the type of bottles in the production lines. Through the machine control panel the operator is able to set a format change in a few seconds, save new recipes and modifying the existing ones

TECHNICAL INFO:

• PRODUCTION: 2400÷3500 pcs/h

• BOTTLES SIZE [mm]: 20 ÷ 200 mm

• POWER CONSUMPTION: 3 KW – 400V/3F/N/T – 50 Hz

• AIR CONSUMPTION: 200 lt./min. a 6 atm

• PLAN DIMENSIONS [mm]: 2555 x 1500 + conveyor exit

• WEIGHT: aprox 500 Kg with accessories

• BOTTLES SIZE [mm]: 20 ÷ 200 mm

• POWER CONSUMPTION: 3 KW – 400V/3F/N/T – 50 Hz

• AIR CONSUMPTION: 200 lt./min. a 6 atm

• PLAN DIMENSIONS [mm]: 2555 x 1500 + conveyor exit

• WEIGHT: aprox 500 Kg with accessories

Request a quote for

Automatic plastic and glass bottles tray denester

Fill this form