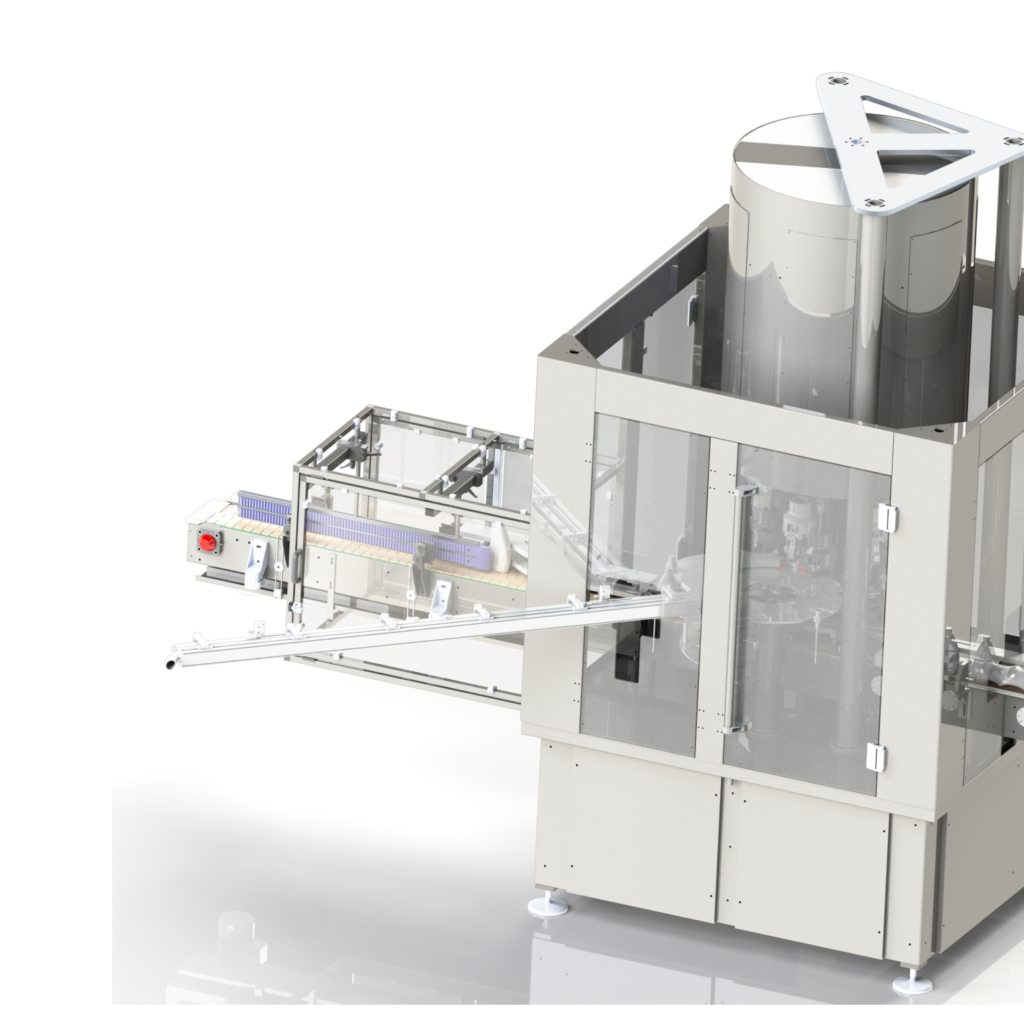

CONTINUOS ROTARY CAPPING MACHINE

The continuous rotary capping machine is suitable for high productivity and it is very precise in cap positioning. It can be made in different versions and for all the type of caps: according to the productivity required it is possible to apply to the machine a proportional number of heads.

These capping machined can be integrated inside the monobloc to apply different closures to the same bottles.

TECHNICAL INFO:

• Electronic rotary capping turret with servo-motorized tightening groups

• From 4 to 24 capping heads for a maximum productivity of 600 bpm

• Interchangeable spindles according to the type of caps with replaceable knurled or rubberized terminals.

• Electronic tightening groups with vertical brushless motorization controlled by electronic cam.

• Cam set by recipe according to the type of cap, bottle height and tightening settings

• Mechanical screwing with hysteresis clutch or servo-motorized with torque control.

• Caps feeding with rotary mechanical sorters

• Caps feeding with rotary mechanical sorters

• From 4 to 24 capping heads for a maximum productivity of 600 bpm

• Interchangeable spindles according to the type of caps with replaceable knurled or rubberized terminals.

• Electronic tightening groups with vertical brushless motorization controlled by electronic cam.

• Cam set by recipe according to the type of cap, bottle height and tightening settings

• Mechanical screwing with hysteresis clutch or servo-motorized with torque control.

• Caps feeding with rotary mechanical sorters

• Caps feeding with rotary mechanical sorters

Maximum productivity: 600 bpm

Request a quote for

Fill this form